The Premise

|

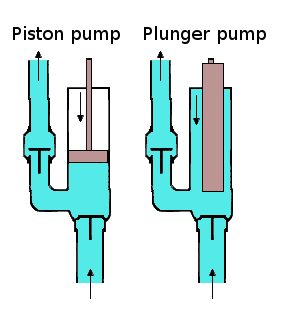

| Fig. 1: A Piston Pump (left). Wikipedia |

Atlanta is hot in the summer, so have a cool drink can become very necessary (especially when wearing a costume at Dragon*Con). Now, a steampunk would not be caught carrying around a CamelBak, and a canteen, while practical, is a bit boring. Why not use a pump to bring fluid from my backpack to a dispenser and maybe find a way to cool it in the process.

I want to create a piston-cylinder device (see Figure 1) to pump fluid through a cooling medium and out of a dispenser. The pump will also be powered by my flywheel. After, a bit of searching, I think I have come up with a simple, easy to build pump.

The Proposed Method

My current idea is to take an empty wine bottle, lop off the bottom, machine an airtight piston to fit inside the bottle, then run the piston using a crank arm. Figure 2 is a conceptual drawing of the idea.

|

| Figure 2: Conceptual Sketch of A Pump. Bottle(Green), Piston(Black), Crank Arms(Blue), Liquid(Teal?) |

As the left-side arm rotates, the piston will create pressure, forcing the fluid out of the mouth of the bottle to the right. It should also be reversible, in order to draw the fluid back into the bottle, for storage.

To cut the bottom off the bottle, I will try this tutorial from GreenPowerScience.com. They get a bit long winded in the video, but thanks to the Wadsworth Constant, you can use this link instead and skip over the fluff.

As for the piston, I have not decided on how to make that yet. I am stuck between two different options:

- Machine metal into shape, and use some rubber grommets to create the seal

- Use a 3D printer to create a piston out of ABS, then machine it to fit

I am leaning more toward #2, but then again, I just really want a Solidoodle.

The interface with the flywheel is probably going to be a combination of a pulley and belt connected to the flywheel shaft, and a worm drive connected to the crank arm. There will also need to be a reversal option available, but that might take the form of a crossed belt drive.

The Concerns

I am concerned about efficiency with this design. The input is coming from a very high rotational velocity(the flywheel) and trying to convert it to a very slow linear velocity(the crank arm). I have a feeling that this mechanism will be more of a metering device than an actual pump. It will take a bit more thought to understand how this system will function.

I will be creating another post about the math behind the pump, after a few considerations for placement and orientation. I primarily wanted to get this information out of my head.

No comments:

Post a Comment